ENHANCED SUSTAINABLE MACHINING

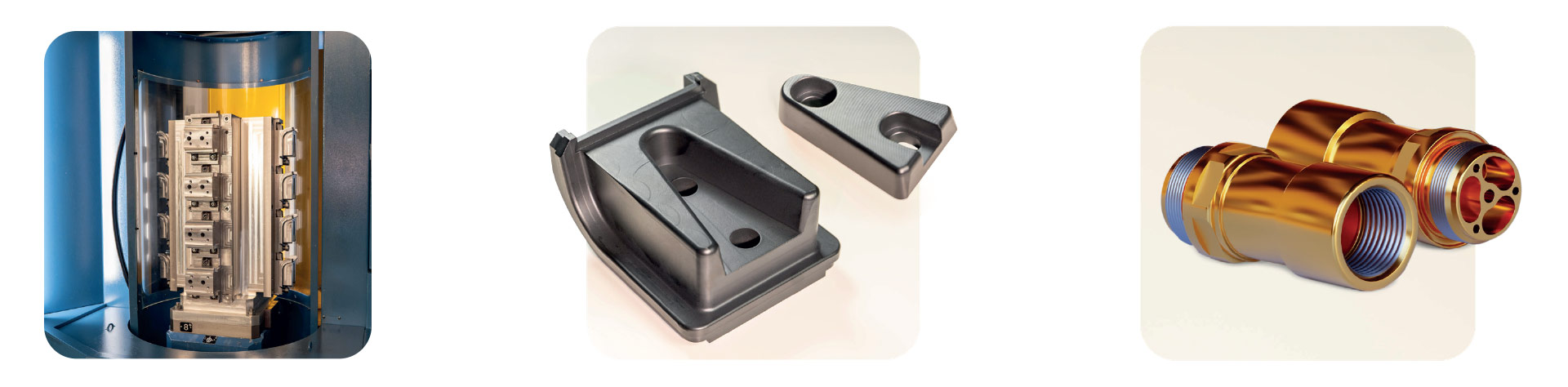

INTRODUCING THE MATSUURA H.PLUS-300 PC15 CNC MILLING MACHINE.

Machined Component Systems commitment to sustainable CNC machining has been strengthened by the introduction of Horizontal Machine Tool Technology. This advanced machining methodology enhances precision and optimises power usage, further advancing energy-efficient operations.

MCS prioritises eco-friendly and socially responsible practices across all manufacturing processes. The MCS approach centres on energy efficiency, perfecting energy use in machining operations with efficient machines, effective programming, and proactive energy management. MCS utilises 100% Green Electricity (GE), generating one-third through photovoltaic solar panels. Waste reduction is vital, achieved by maximizing material usage, recycling, and reusing waste like swarf and bar-ends. Water conservation is implemented via filtration and recycling of water from machining coolant. Emissions are curbed with dust and fume extraction systems. Our transport will be electrified, reducing carbon emissions and noise pollution. MCS is socially responsible and adheres to ISO 14001 environmental management standards, setting a benchmark for sustainable manufacturing.